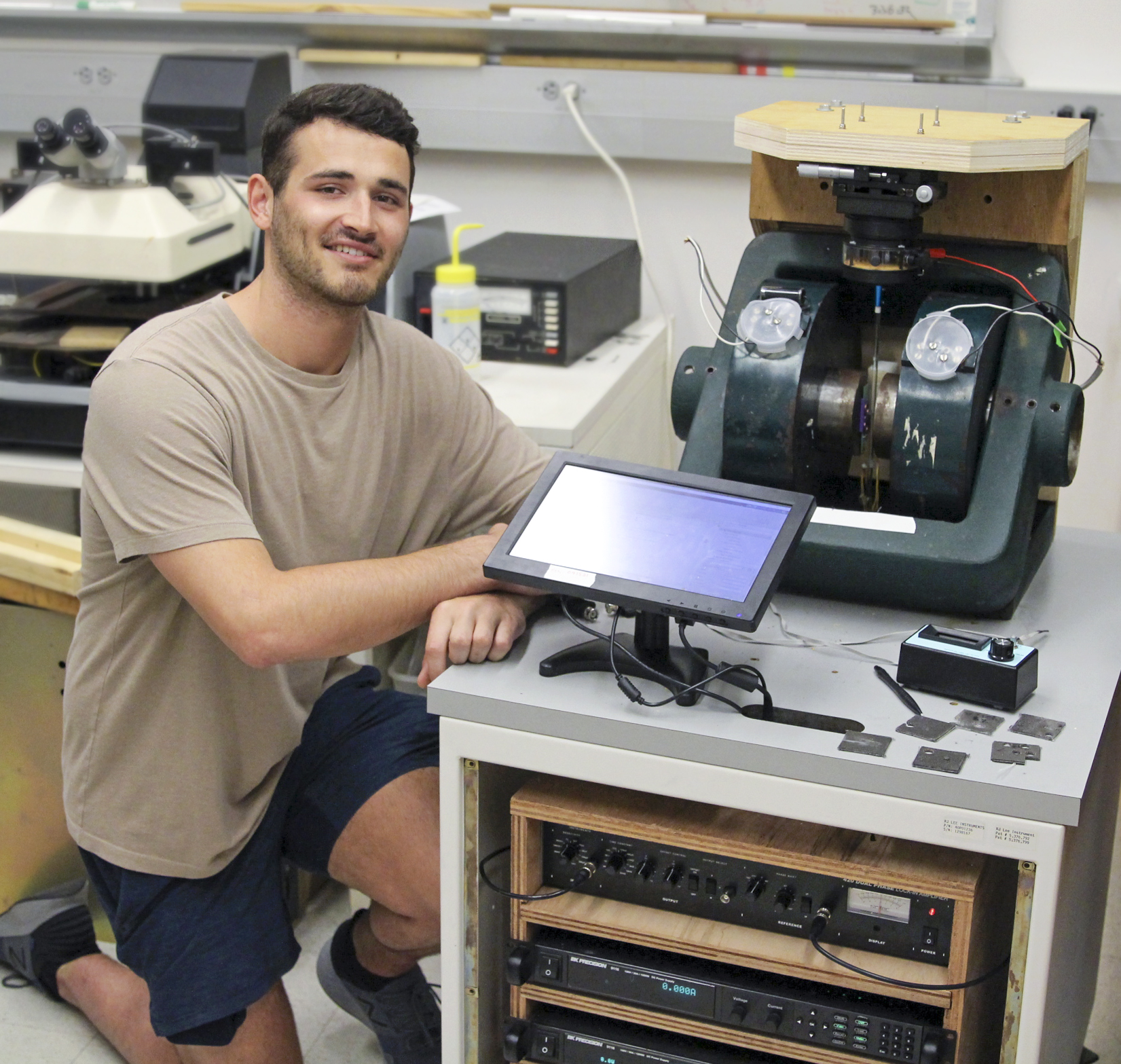

During his undergraduate career, Bacogeorge built an automated vibrating-sample magnetometer. The device will advance current and future physics research on magnetic polymers, Professor Ben Evans said.

It started with a pat on the shoulder and a leap of faith in Stratton Bacogeorge’s freshman year of 22 at Elon.

Gradually, over the next three years, he designed and built an automated vibrating-sample magnetometer. When he graduates with his engineering degree later this month, he will leave behind an instrument that characterizes magnetic polymers by rapidly vibrating them, inducing a current through a magnetic field, and recording their reactions.

Bacogeorge’s magnetometer boosts Elon’s physics research capabilities. Current projects – examining the potential for disinfection of medical implants without magnetic induction surgery and understanding the magnetic properties of metals encased in soft materials – as well as future projects will benefit from the device.

“It is an important tool for a magnetism workshop, where it is necessary to be able to characterize the responses of a material to a magnetic field. There are a lot of projects that will move forward,” said physics professor Benjamin Evans. “This magnetometer allows us to get the magnetic characterization we need for publications and materials design.”

Commercial magnetometers start at around $150,000. Relying on courage and ingenuity, Bacogeorge built one for around $7,000 with funds from a National Science Foundation grant that Evans received in 2017 and the TE Powell Jr. ‘Evans. The device approaches 1 Tesla of current – or one Newton of force per ampere of current per meter of conductor. For comparison, a strong fridge magnet produces about 0.01 T, so the lab magnet is 100 times stronger.

The project began in an after-class conversation during Bacogeorge’s freshman year. Enrolled in the Evans section of General Physics II, he was attracted by the good humor of the professor and his investment in the subject. When Evans learned of Bacogeorge’s interest in engineering, he pitched the project: “If I gave you a magnet to start with, do you think you could design it?” he asked Bacogeorge .

It quickly became Bacogeorge’s hobby: learning the physics behind magnets and magnetic fields, reading articles about how vibrating-sample magnetometers work, sourcing the necessary parts, and writing software to operate the system and automate data collection. Free hours were spent in the physics lab, working with a large, old-looking magnet that had previously been gathering dust in a corner of the McMichael Science Center.

“The first year was spent learning the real physics behind it. I was really in over my head,” Bacogeorge said. “I wasn’t sure what to do but I could see an end goal.”

Bacogeorge often met with Evans, who advised him and procured additional material. Presentations at National Undergraduate Research Conferences and Elon’s Spring Undergraduate Research Forum followed during his graduate years. This year, the project became a credited independent research course, leaving time and structure to complete the magnetometer.

“Working with Dr. Evans, I’m like an engineer working under my supervisor, who reports to him weekly,” Bacogeorge said. “This year has been focused on signal detection, designing the detection coils themselves, and communicating the whole system as a single unit. Before I graduate, I want to be able to get a curve of full sample hysteresis, which is the characterization we look for when testing a sample.

“Stratton is an engineer,” Evans said. “He finds a project or something that needs to be done, and he finds how to do it. This independence was there from the start.

In addition to magnetometer research, Bacogeorge was a member of a senior team that investigated the use of laser Raman spectroscopy to identify surface defects on silicon carbide wafers as part of the Senior Engineering Project Capstone design. These wafers are used as semiconductors in microchips that power electronic devices. Defects on the surface of the wafer can cause the devices to malfunction. The project was sponsored by Wolfspeed of Durham.

After graduating, Bacogeorge accepted a position in Wastequip’s Engineering Leadership Development Program. He will spend the next few years learning various aspects of the Charlotte-based waste handling equipment manufacturing business. He joins former engineer Matthew Del Valle ’21 in the company’s Engineering Leadership Program.

“When I was a freshman, I couldn’t see myself doing research in physics. Now I am immersed in magnetic physics research,” Bacogeorge said. “It’s very cool to leave something behind at Elon.”